Fuel Polishing & Cleaning

FUEL HANDLING

Handy Fuel WA’s fuel polishing systems are designed for bulk and minor volumes of fuel. It works by pumping the fuel through a series of filtration stages, removing contaminants down to 1 micron level thus obtaining maximum levels of efficiency for removing free and problematic emulsified water content.

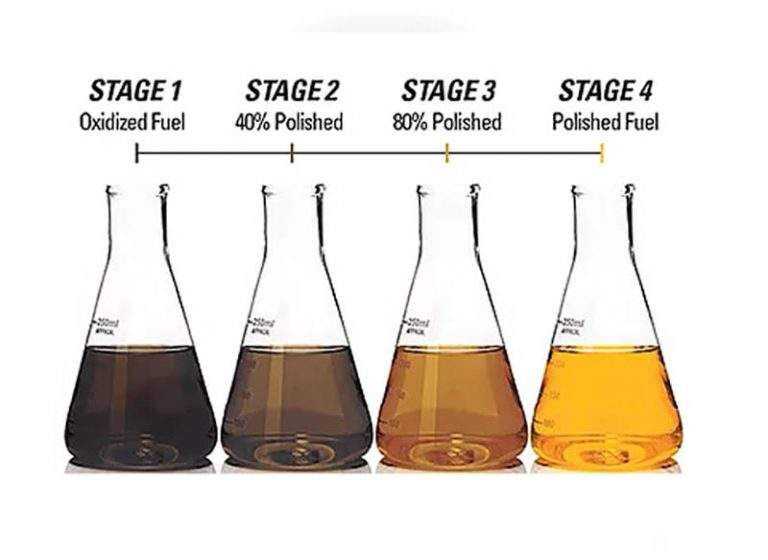

Our stage filtration design allows fuel to flow through the internal core of the media to filter out large contaminants, debris, microbial growth and freestanding residual water. The fuel is then passed through the specially engineered layers of pleated media within the filter stages to remove emulsified water and fine contaminants, resulting in fuel restoration. This process minimises your diesel storage tanks foreign particulate, sludge and emulsified water content. This also prevents these contaminants being delivered through the delivery chain of your valuable dispensing equipment and even worse, making it’s way through to your machinery, vehicles, generator sets etc.

By maintaining your storage tank and keeping your fuel clean you will greatly reduce operating costs and downtime in the result of a breakdown.

Supplying your engines with low-quality or contaminated fuel is never a good option. If you have diesel storage tanks on site, you should know that not all fuel filtration systems are designed equal. Most systems, including engine fuel system filters will only remove larger contaminants and freestanding water and allow passage of smaller micron sized contaminants. This will eventually lead to costly repairs to engines/equipment and downtime, both of which are highly undesirable by any operators.

Handy Fuel WA can remedy any fuel quality issues by installing action and prevention measures in regards to your stored fuel.

We can:

✓ Conduct a site visit to survey and sample fuel pre-works.

✓ Send sample for laboratory testing.

✓ Obtain results & evaluate fuel remedial measures.

✓ Conduct fuel and/or tank cleaning.

✓ Take a sample post-cleaning & send for analysis.

✓ Report all laboratory & site findings to the client.

HOW DOES IT WORK?

The process of fuel polishing relies upon a sophisticated combination of filtration and depolymerisation.

The cleanliness of diesel in the past was not as significant an issue as it is today. With common rail engine fuel delivery systems operating at such high pressures and fine tolerances, fuel filtration of the highest standard is now an operational necessity.